Air conveyors are most frequently employed to move soft goods like empty containers, boxes, and trays. A class of equipment known as an “air conveyor” uses air to transport goods and materials rather than mechanical belts or chains with speeds frequently reaching 1,000 fpm. They are not, however, just used with lightweight materials. Instead, materials-handling devices called air conveyors transport various things using pressurized air. Read More…

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

Founded in 1995, IEDCO specializes in custom-engineered powder handling solutions for the Pharmaceutical, Food, and Fine Chemical industries. From pneumatic conveying systems to comprehensive process designs, we deliver reliable, ergonomic, and innovative technologies. With decades of expertise and a client-focused approach, IEDCO is your single-source solution for tailored systems to enhance...

At Akona Process Solutions, we take pride in designing and delivering pneumatic conveying systems that keep bulk material handling safe, efficient, and reliable. We have built our expertise around developing equipment that moves powders, granules, and other bulk solids with precision, minimizing downtime and maximizing productivity for our customers.

When it comes to pneumatic conveying, Air Systems Design has been in business since 1984, a family owned business. Is dedicated to providing only the highest quality dust and baling systems available. Our team works together to ensure that we bring you the most technologically advanced products on the market, as well as that our company stays on the forefront of innovation at all times. To learn...

More Air Conveyor Manufacturers

Air conveyors play a crucial role in modern manufacturing, warehousing, and industrial automation facilities that produce and sell vast quantities of goods. By leveraging the principles of pneumatic conveying, these advanced systems enable efficient, high-speed movement of products, materials, and bulk solids from one location to another within a facility. Companies seeking to maximize throughput, reduce manual labor, and streamline material handling processes often turn to air conveyors—also referred to as pneumatic conveyors—as an essential component of their automation strategy.

Comprehensive Guide to Air Conveyors: Principles, Types, Benefits, and Industry Applications

Are you searching for ways to improve your facility’s material transport efficiency, reduce downtime, or handle delicate or bulk materials safely? This detailed guide covers everything you need to know about air conveyor systems, including operational principles, types, practical benefits, common applications, and tips for selecting the best air conveyor manufacturer for your needs.

Operational Principles of Air Conveyors

Air conveyors, a subset of the broader pneumatic conveying systems family, use pressurized air or vacuum to move materials through enclosed pipelines or plenum spaces. The technology’s roots trace back to early industrial setups, where a simple pipe and a blower sufficed to transport lightweight materials like sawdust. In these internal air conveyors, the airflow—generated by industrial blowers—pushes or pulls items through the transport line. As a result, the goods being conveyed remain suspended or guided within the moving air stream, effectively minimizing friction and manual handling requirements.

External, or plenum-based, air conveyors operate on a slightly different principle. Here, a blower or fan pressurizes a chamber (plenum), directing air through specialized nozzles or louvers aimed at the items to be conveyed. The resulting air jets propel products along a defined path, often with the help of low-friction rails, guides, or decks to maintain orientation and prevent jams. Some advanced hybrid systems combine these principles by using multiple plenums and directional louvers, enabling the transport of challenging materials such as scrap metal or oddly shaped parts.

One of the primary engineering considerations in air conveyor system design is pressure loss. Internal air conveyors are typically limited to lengths under 100 feet due to the pressure drop along the pipe. In contrast, hybrid and external plenum designs can extend much further, making them suitable for large-scale facilities. To ensure optimal performance, it is vital to minimize friction between the product and the conveyor surfaces. Early air conveyors achieved this by introducing an air boundary layer along the pipe’s interior, reducing drag and energy consumption.

Key Features of Air Conveyor Operation

- Minimal contact and friction with transported materials

- Continuous or intermittent flow options

- Energy-efficient airflow management

- Flexible routing and integration with existing equipment

- Reduced risk of product contamination or damage

Types of Air Conveyors

Choosing the right air conveyor design is crucial for achieving specific production goals, handling diverse product types, and meeting safety or regulatory requirements. Air conveyors can be classified by their construction, airflow pattern, and the nature of items they handle. Below are the most popular categories:

Deck Conveyors

Deck conveyors are engineered to partially lift and float lightweight products—such as cans, bottle caps, cartons, or cases—slightly above the conveying surface using air jets. This design mimics the action of an air hockey table: perforated decks and strategically placed louvers produce a cushion of air that supports and gently propels items forward. The benefits of deck conveyors include reduced friction, minimized product abrasion, and the ability to move items at steep inclines (often greater than 10 degrees).

In certain industries, specialized “tunnel tracks” with both top and bottom decks are used to vertically elevate products, such as empty aluminum cans or plastic bottles, between floors. However, proper product alignment is essential—deformed or irregularly shaped containers may not float correctly, leading to jams or airflow inefficiency. To address this, deck conveyor systems employ adjustable side and top guides, ensuring items remain upright and in the optimal position for air flotation. These features make them ideal for high-speed packaging lines, beverage bottling plants, and food processing facilities.

Neck Ring Conveyors

Neck ring air conveyors are tailored for transporting plastic bottles by capturing and supporting the bottle at the neck ring—the reinforced ridge located below the threaded cap area. These systems employ paired, low-friction rails running parallel, providing a secure yet gentle grip for bottles throughout the conveyor’s length. Pressurized air directed along the rails reduces drag and accelerates bottle movement, making neck ring conveyors indispensable for high-volume beverage, personal care, and pharmaceutical bottling operations. Their modular design allows easy integration with blow molding machines, filling lines, and labeling equipment.

Bulk Conveyors

Bulk air conveyors represent the oldest and simplest form of pneumatic conveying. At their core, these systems are enclosed tubes or ducts, equipped with high-capacity blowers that generate a fast-moving air stream. Materials—ranging from grains, food powders, and plastic pellets to metal scrap and coal—are introduced into the airstream, which suspends and transports them to the desired location. Bulk conveyors can be fully enclosed for dust control or incorporate access ports and louvers to regulate flow and prevent material buildup.

Modern bulk handling air conveyors are engineered for continuous, automated operation in industries such as agriculture, mining, chemical processing, plastics manufacturing, and power generation. They are valued for their ability to move large volumes of bulk solids quickly, safely, and with minimal manual intervention. Custom features such as abrasion-resistant linings, automated feed hoppers, and discharge valves further enhance reliability and operational efficiency.

Benefits and Drawbacks of Air Conveyors

Implementing an air conveyor system delivers significant advantages for companies managing bulk materials, fragile goods, or high-throughput production lines. Here are the primary reasons businesses invest in pneumatic conveying solutions:

Advantages of Air Conveyor Systems

- Efficiency and Throughput: Air conveyors enable rapid, continuous movement of products, reducing bottlenecks and increasing production capacity compared to traditional belt or roller conveyors.

- Gentle Handling: The air cushion minimizes direct contact, protecting delicate or lightweight items from abrasion, deformation, or contamination—ideal for food processing, pharmaceuticals, and electronics manufacturing.

- Flexibility: Customizable layouts and modular construction allow seamless integration with existing equipment and easy adaptation to facility changes or expansions.

- Sanitation and Containment: Enclosed systems help control dust, fumes, and product spillage, supporting regulatory compliance in food, chemical, and pharmaceutical plants.

- Reduced Labor Costs: Automation of material handling reduces reliance on manual labor, improving workplace safety and lowering operational expenses.

- Versatility: Capable of conveying a wide range of materials, including powders, pellets, grains, tablets, plastics, textiles, and more.

- Low Maintenance: Fewer moving parts result in decreased wear, less downtime, and simplified maintenance routines.

Potential Limitations and Considerations

- Energy Consumption: Air conveyors can be more energy-intensive than mechanical conveyors, especially when handling heavy or dense materials.

- Material Suitability: Not all materials are compatible with pneumatic conveying—sticky, abrasive, or large items (such as gravel, boulders, or wet substances) may cause blockages or excessive wear.

- System Design Complexity: Customized engineering is often required to optimize airflow, pressure, and material feed rates for specific applications.

- Initial Investment: Upfront costs for pneumatic conveying equipment and installation can be higher than simple mechanical conveyor systems, but are often offset by long-term operational savings.

Wondering if air conveyors are the right fit for your specific material handling challenge? Contact a specialized air conveyor manufacturer for a system evaluation, or explore our directory to compare suppliers and request tailored quotes. Understanding your material properties, required throughput, and facility layout is essential for making an informed investment.

Applications of Air Conveyors

Air conveyor systems are widespread across numerous sectors that demand rapid, hygienic, and reliable movement of products or bulk materials. Below are some of the most prominent industry applications:

- Food and Beverage Processing: Transporting bottles, cans, cartons, powders, grains, and ingredients between production, filling, and packaging stages with minimal contamination risk.

- Pharmaceutical Manufacturing: Conveying tablets, capsules, powders, and vials in sterile or cleanroom environments, ensuring product integrity and regulatory compliance.

- Plastics and Chemical Production: Moving plastic pellets, resins, chemicals, and additives to molding, extrusion, or mixing stations efficiently and safely.

- Mining and Minerals: Handling coal, ores, aggregates, and minerals in bulk, including dust control and high-volume transfer over long distances.

- Textile Industry: Automated transfer of fibers, yarns, and fabrics to and from processing equipment, reducing manual labor and improving process flow.

- Glass Manufacturing: Moving fragile bottles and containers through inspection, filling, and packaging lines without surface damage.

- Powder Coating and Surface Finishing: Conveying fine powders, dusts, or abrasive materials in closed systems to maintain air quality and protect worker health.

- Electronics and Precision Manufacturing: Gentle handling of sensitive components, circuit boards, or microchips during assembly and packaging.

- Automotive and Aerospace: Transporting small parts, fasteners, and lightweight components in assembly lines for cars, airplanes, and watercraft.

- Waste Management and Recycling: Moving scrap metal, plastics, paper, and hazardous waste safely and efficiently for sorting, processing, or disposal.

Curious about how air conveyor systems can be customized for your industry, facility, or product type? Explore real-world case studies, or connect with leading air conveyor suppliers to discuss your specific requirements.

Key Decision Factors When Selecting an Air Conveyor System

Choosing the ideal air conveyor involves several technical and operational considerations to ensure optimal performance and return on investment. Here’s what to evaluate as you compare air conveyor systems and manufacturers:

- Material Type and Characteristics: Understand the size, shape, density, abrasiveness, and moisture content of the items or bulk solids you need to convey.

- Conveyor Length and Routing: Assess facility layout, required transport distances, elevation changes, and potential integration points with existing equipment.

- Throughput and Speed Requirements: Define your target production rates, peak loads, and any batch or continuous operation needs.

- Cleanliness and Containment: Consider sanitary design features, dust control, and cleanliness standards, especially for food, pharmaceutical, or chemical applications.

- Energy Efficiency: Evaluate blower size, air management technologies, and system controls to minimize operational costs.

- Maintenance and Service: Look for easy-access components, robust construction, and available technical support or spare parts.

- Regulatory Compliance: Ensure the system meets industry-specific regulations for safety, hygiene, and environmental protection.

- Budget and Total Cost of Ownership: Balance initial investment with anticipated labor savings, energy costs, and long-term reliability.

Need help evaluating air conveyor options for your facility? Ask yourself:

- What types of products or materials am I moving?

- What are my key pain points—speed, contamination, manual handling, or space constraints?

- How will the conveyor integrate with upstream and downstream processes?

- What are my maintenance resource and training needs?

How to Choose the Right Air Conveyor Company

Securing the best air conveyor for your unique requirements starts with selecting a knowledgeable and experienced supplier. Here’s how to approach the decision-making process:

- Compare at least 4 to 5 air conveyor manufacturers using a comprehensive air conveyor directory to review business profiles, product offerings, and customer reviews.

- Visit each company’s website—use proprietary preview tools if available—to understand their specialties, industries served, and engineering capabilities.

- Contact suppliers directly through online forms or RFQ (Request for Quote) tools to ask about system customization, delivery timelines, after-sales support, and pricing.

- Ask about previous installations, case studies, and references for projects similar to yours.

- Seek out suppliers with in-house engineering, installation, and maintenance support to streamline your project and ensure ongoing reliability.

Ready to take the next step? Request a quote or schedule a consultation with leading air conveyor manufacturers to discuss your project goals, budget, and technical needs.

Frequently Asked Questions About Air Conveyors

What maintenance do air conveyors require?

Air conveyors offer low-maintenance operation thanks to their minimal moving parts. Routine tasks typically include filter checks, blower inspection, periodic cleaning of ducts and nozzles, and monitoring of airflow or pressure levels. Many modern systems feature automated diagnostics to alert operators to potential blockages or performance issues.

How energy efficient are pneumatic conveyor systems?

Energy efficiency depends on system design, material type, and operational parameters. While air conveyors may use more energy than basic mechanical conveyors for dense materials, advanced blower technologies, optimized routing, and variable speed controls can significantly reduce energy consumption. Proper system sizing and maintenance are key to maximizing efficiency.

Can air conveyors handle hazardous or sensitive materials?

Yes. Enclosed air conveyor systems are widely used for hazardous waste, pharmaceutical powders, chemicals, and food ingredients, offering containment, dust control, and contamination prevention. It’s important to specify system features (such as explosion-proof motors or HEPA filtration) for safety and regulatory compliance.

How do I determine the right air conveyor size and configuration?

Work with an experienced air conveyor supplier who can assess your facility layout, material characteristics, throughput goals, and integration points. Most manufacturers offer system design services, site visits, and pilot testing to validate performance before full-scale installation.

What are typical lead times for air conveyor system installation?

Lead times vary by project scope, customization level, and supplier. Standard systems may be delivered within 8–12 weeks, while highly customized or large-scale projects can take longer. Early engagement with suppliers is recommended to align with production schedules and minimize disruption.

Conclusion: Unlocking Efficiency with Air Conveyors

Air conveyor systems are a transformative solution for manufacturers and processors seeking to optimize material flow, enhance product quality, and achieve cost-effective automation. By leveraging pneumatic conveying technology, companies can move a wide variety of materials—ranging from lightweight plastics and food products to bulk solids and hazardous waste—quickly, safely, and with minimal labor. With multiple design options and industry applications, air conveyors deliver flexibility, reliability, and value in today’s competitive landscape.

If you’re considering upgrading your facility’s material handling capabilities, explore our directory of air conveyor suppliers or request a custom quote to get started. For further insights, check out our case studies, technical guides, and buyer’s checklists—empowering you to make the best decision for your business.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

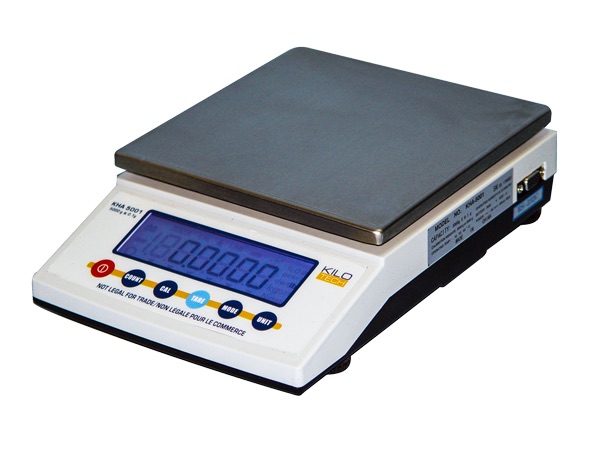

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services