Akona Process Solutions

Akona Process SolutionsRequest A Quote

Monroe, NC | 877-463-1866https://akonasolutions.com/brands/who-is-spiroflow/

At Akona Process Solutions, we take pride in delivering high-performance mixing equipment tailored to the unique demands of the concrete, construction, and industrial processing industries. Our expertise lies in designing and manufacturing a wide range of advanced mixers, each engineered for reliability, efficiency, and consistency in even the most rigorous production environments. Whether our customers require planetary mixers, twin-shaft models, or ribbon and paddle mixers, we build solutions that are optimized for maximum throughput and long-term durability. We don’t just build machines—we engineer process solutions. Our team works closely with clients to develop integrated systems that enhance material flow, reduce downtime, and support automated operations. From initial design to installation and ongoing service, we focus on delivering comprehensive support that ensures our equipment performs at its best across every phase of operation. Our mixers are often integrated into complete batching systems, and we tailor these systems to fit the exact workflow and technical requirements of each facility we serve. As innovators in process equipment, we continue to refine our manufacturing techniques and control technologies, giving our customers the edge in quality control and production efficiency. Our commitment to craftsmanship and service extends well beyond delivery. We remain a long-term partner to our clients, offering maintenance, retrofitting, and technical support to keep their operations running smoothly and cost-effectively. With every system we deliver, we bring decades of experience and a deep understanding of what it takes to succeed in high-demand processing environments.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

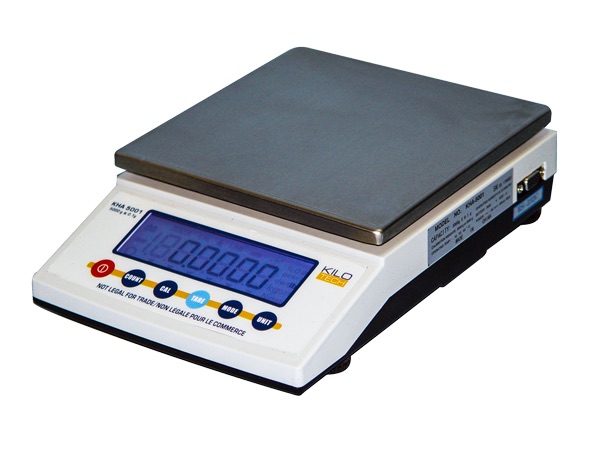

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services