Pneumatic conveying is an effective way of handling and moving different types of bulk powdered and granular products with negligible loss and at a lower cost than other systems. These products usually consist of granules or powders. These systems move materials via enclosed, airtight pipes by combining airflow, gas, and pressure. Read More…

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

Founded in 1995, IEDCO specializes in custom-engineered powder handling solutions for the Pharmaceutical, Food, and Fine Chemical industries. From pneumatic conveying systems to comprehensive process designs, we deliver reliable, ergonomic, and innovative technologies. With decades of expertise and a client-focused approach, IEDCO is your single-source solution for tailored systems to enhance...

At Akona Process Solutions, we take pride in designing and delivering pneumatic conveying systems that keep bulk material handling safe, efficient, and reliable. We have built our expertise around developing equipment that moves powders, granules, and other bulk solids with precision, minimizing downtime and maximizing productivity for our customers.

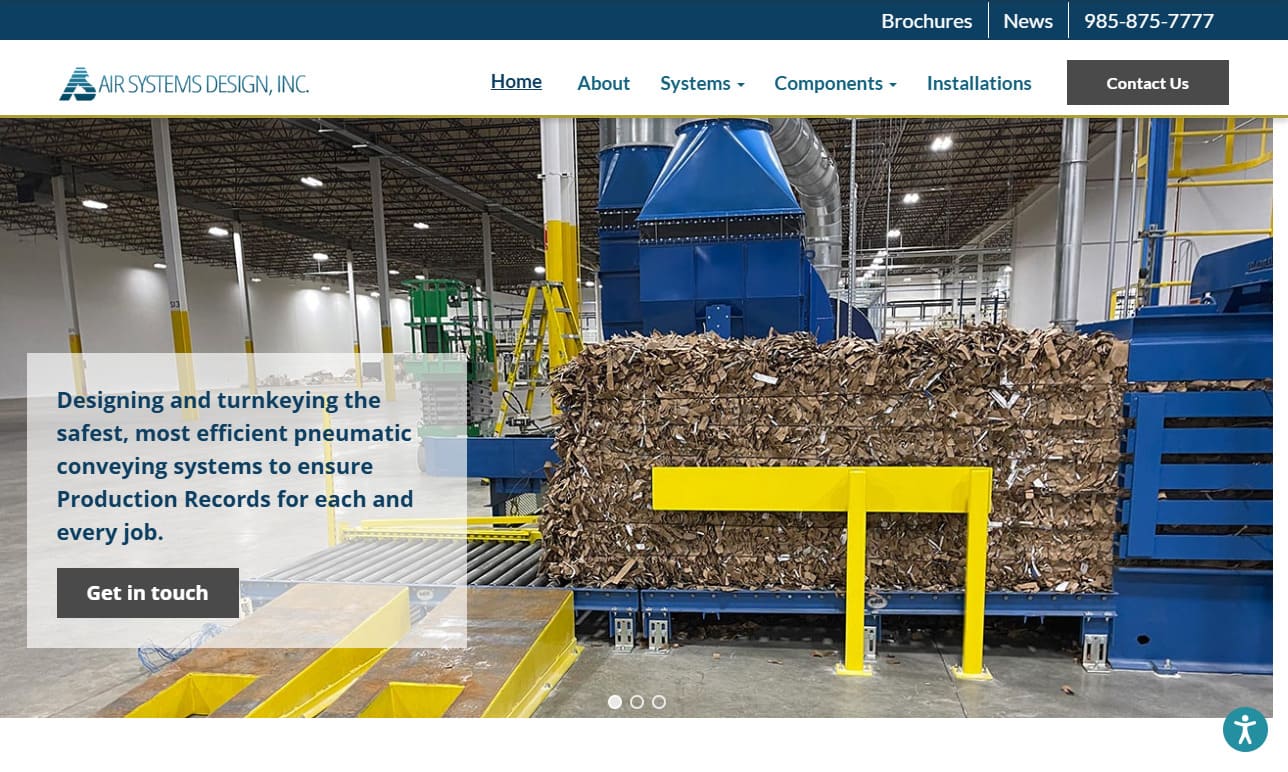

When it comes to pneumatic conveying, Air Systems Design has been in business since 1984, a family owned business. Is dedicated to providing only the highest quality dust and baling systems available. Our team works together to ensure that we bring you the most technologically advanced products on the market, as well as that our company stays on the forefront of innovation at all times. To learn...

More Pneumatic Conveying Manufacturers

Operators can control negative or positive pressure of airflow to smoothly move products without worrying about loss or damage. Pneumatic conveying systems have revolutionized bulk material handling across a wide range of industries—from food processing and pharmaceuticals to plastics, chemicals, cement, and power generation. By leveraging compressed air or gas to propel particles, powders, and granules through enclosed pipelines, these systems ensure safe, efficient, and contamination-free transfer of materials across manufacturing plants and warehouses.

What Is a Pneumatic Conveying System?

A pneumatic conveying system is an advanced material handling technology that utilizes air pressure differentials to move bulk solids, powders, pellets, or granular materials through pipelines. These systems are fundamental to modern industrial automation, eliminating the need for manual transport and minimizing product contamination. Pneumatic conveyors are ideal for applications requiring dust control, high throughput, and flexible routing, making them a preferred solution in diverse sectors including agriculture, chemical processing, pharmaceuticals, food and beverage, and more.

How Does a Pneumatic Conveyor Work?

— Understanding the Working Principle of Pneumatic Conveying Systems

A pneumatic conveying system works by moving air through pipes, conveying a propulsion force that transports bulk products via the system from end to end. This movement relies on a pressure difference between the system's start and endpoints, achieved through compressors, blowers, or industrial fans. The airflow entrains and suspends material particles, propelling them through the pipeline at controlled velocities.

The pressure differential is influenced by the system's layout, pipe length, diameter, and the characteristics of the conveyed product, such as particle size, moisture content, and bulk density. The specific conveying method (dense or lean phase) determines the flow regime and the design parameters, ensuring product integrity and system efficiency. Properly engineered pneumatic systems ensure reliable, continuous operation and minimal maintenance.

Types of Pneumatic Conveying Systems: Choosing the Right Solution for Your Application

There are two main types of pneumatic conveying systems: dense phase and lean phase (also known as dilute phase). Understanding the differences between these systems and their subcategories is critical for selecting the best solution for your bulk material handling requirements. Factors such as particle size, abrasiveness, fragility, and required conveying distance all influence the choice of system design.

Lean Phase Pneumatic Conveying

The most widely used system, lean phase pneumatic conveying (or dilute phase conveying), is ideal for transporting light, free-flowing powders and granules over moderate distances. This method is characterized by high-velocity air streams that keep the particles suspended throughout the pipeline, ensuring smooth, continuous flow. Lean phase systems are generally divided into two subtypes based on air velocity and pressure:

Dilute Phase Pneumatic Conveying

Dilute phase conveying systems operate with gas velocities typically greater than 17 to 18 m/s and a vacuum or pressure below 0.1 bar. In this mode, material such as powders or granules is fully suspended in the airflow, resulting in a low solid loading ratio. Dilute phase pneumatic conveying is suitable for handling non-abrasive, lightweight materials such as flour, sugar, plastic pellets, and pharmaceutical powders. Most systems utilize industrial fans, positive displacement blowers, or side channel blowers to create the necessary airflow and transport the product efficiently along the pipelines.

Medium Phase Pneumatic Conveying

Medium-phase pneumatic conveying is suitable for applications requiring slightly higher solid loading than dilute phase systems. Here, air or gas velocities also exceed 17 to 18 m/s, but system pressures can reach up to 0.35 bar. The transported material remains suspended but at a higher concentration. Exhauster fans and root blowers are commonly used to push air through the system. Medium phase conveying bridges the gap between dilute and dense phase systems and is chosen for materials that require gentle handling but with higher throughput rates.

Dense Phase Pneumatic Conveying

Dense phase conveying systems are designed for moving fragile, abrasive, or heavy-bulk density products at low velocities, typically below 8 m/s. Unlike lean phase, dense phase conveying involves the movement of materials in slugs, plugs, or waves, rather than in a fully suspended state. This method is ideal for minimizing product degradation and reducing pipeline abrasion, making it suitable for conveying sensitive materials such as food grains, carbon black, cement, sand, or plastic resins. Dense phase systems use controlled pulses of air to gently push the product, followed by another pulse of both product and air, ensuring precise, low-speed product movement.

Dense phase conveying requires precise calculations for system design, including particle size analysis, product density, moisture content, and conveying route length. Proper system engineering ensures reliable operation, product quality, and energy efficiency.

Key Advantages of Pneumatic Conveying Systems

Pneumatic conveying systems offer a host of benefits compared to conventional mechanical conveying solutions. Wondering why so many industries are switching to pneumatic conveyors? Here are some of the primary advantages:

- Flexibility in Routing: Pneumatic conveyors can transport materials over long distances, both vertically and horizontally, enabling efficient plant layouts and streamlined production lines.

- Space-Saving Design: The compact pipeline design allows systems to be routed around existing equipment, using minimal floor space and adapting to complex facility layouts.

- Enclosed, Dust-Free Operation: The fully enclosed nature of pneumatic conveying prevents dust emissions, ensuring a clean working environment and reducing the risk of product contamination.

- Safe and Hygienic Material Handling: Enclosed pipelines protect products from external pollutants, making pneumatic conveyors ideal for industries with strict hygiene standards, such as food, pharmaceuticals, and chemicals.

- Low Maintenance and Reliability: With fewer moving parts compared to mechanical conveyors, pneumatic systems offer lower maintenance costs, reduced downtime, and increased reliability.

- Multiple Inlet and Discharge Points: Pneumatic systems can be engineered with multiple pick-up and release points, supporting complex production processes and batch operations.

- Controlled Environment: Operators can maintain a precisely controlled atmosphere, including temperature and humidity, to preserve sensitive products during transport.

- Energy Efficiency: Properly designed systems optimize energy use, reducing operational costs over the system's lifetime.

- Scalability: Pneumatic conveying systems are highly scalable, allowing for simple expansion or modification as production needs change.

Applications of Pneumatic Conveying Systems

Pneumatic conveying is a versatile solution used in a wide variety of industries. Whether you're handling powders, granules, pellets, or abrasive materials, pneumatic conveyors provide efficient, dust-free, and gentle transfer. Explore common applications for each conveying phase:

Common Applications of Dilute Phase Systems

- Free-flowing powders such as flour, starch, sugar, baking soda, and spices

- Light bulk density materials like plastic pellets, PVC resin, or cereal grains

- Products that are resistant to breakage, including chemicals, coffee beans, and food additives

- Pharmaceutical powders and excipients

- Recycled plastics, lightweight minerals, and fine granules

Common Applications of Dense Phase Systems

- Abrasive materials such as silica sand, alumina, cement, and sugar crystals

- Heavy-bulk density products including metal powders, glass beads, and foundry sands

- Blended or fragile products such as food grains, breakfast cereals, or catalyst beads

- Particularly friable materials like carbon black pellets or specialty chemicals

- Plastic pellets, glass batch, minerals, and products not requiring continuous delivery

- Dense phase conveying for sensitive, heat-sensitive, or abrasive materials

Pneumatic conveying is also found in dust collection systems, vacuum conveying for pharmaceutical cleanrooms, bulk unloading and loading, silo transfer, reactor feeding, and automated packaging lines. The adaptability of these systems makes them a cornerstone of modern material handling solutions.

Key Considerations for Designing a Pneumatic Conveying System

Are you evaluating pneumatic conveying system options for your facility? Successful system design requires careful consideration of several factors to ensure optimal performance and product quality:

- Material Characteristics: Assess particle size, shape, abrasiveness, moisture content, and bulk density to select the appropriate conveying phase and equipment.

- Conveying Distance and Routing: Calculate pipeline length, number of bends, vertical lifts, and overall layout to minimize pressure drop and maximize efficiency.

- Air Supply and Filtration: Choose the right type and capacity of blowers, compressors, and filtration systems to maintain consistent air quality and flow.

- System Capacity: Determine required throughput (tons/hour or kg/hour) based on plant production rates, storage capacities, and process integration.

- Handling Fragile or Abrasive Products: Select dense phase systems for delicate or abrasive materials, and consider wear-resistant pipe linings for high-impact applications.

- Maintenance and Access: Design access points for routine inspection, cleaning, and maintenance to minimize downtime and prevent blockages.

- Automation and Controls: Integrate sensors, PLCs, and automation for real-time monitoring, process optimization, and safety interlocks.

- Compliance and Safety: Ensure systems meet industry regulations (such as ATEX, FDA, or GMP) for dust control, explosion protection, and material purity.

Comparing Pneumatic Conveying to Mechanical Conveyors

When should you choose a pneumatic system over a mechanical conveyor (such as a screw conveyor, belt conveyor, or bucket elevator)? Pneumatic conveying is often preferred for its enclosed, dust-free operation, flexibility, and ease of maintenance. Mechanical conveyors may be chosen for extremely coarse, lumpy, or sticky materials that are difficult to convey pneumatically, or when extremely high throughput rates are required over short distances. For most bulk powder handling, pneumatic conveying provides greater hygiene, lower labor costs, and easier plant integration.

Not sure which system is right for you? Ask our experts for a free system evaluation and quote.

Industries That Benefit from Pneumatic Conveying

Pneumatic conveying technologies play a critical role in numerous industries, including:

- Food and Beverage: Transferring flour, sugar, spices, grains, and additives in bakeries, snack processing, and beverage production

- Pharmaceuticals: Cleanroom vacuum conveying of powders, granules, and active ingredients, ensuring GMP and FDA compliance

- Chemicals: Handling resins, catalysts, pigments, and specialty chemicals under controlled environments

- Plastics: Conveying plastic pellets, PVC compounds, and masterbatch between silos, mixers, and extruders

- Cement and Minerals: Bulk transfer of cement, fly ash, lime, gypsum, and sand in building materials production

- Power Generation: Fly ash conveying in coal-fired plants, biomass fuel transport, and desulfurization processes

- Agriculture: Grain, seed, and feed conveying for silos, blending systems, and animal nutrition plants

- Recycling and Waste Management: Moving plastic flakes, shredded paper, and light metals in recycling facilities

How to Choose a Pneumatic Conveying Company

To ensure the best results when selecting a pneumatic conveying company, it's vital to evaluate several providers based on technical expertise, industry experience, and service capabilities. Our pneumatic conveying directory allows you to compare at least four leading companies. Each business profile page highlights areas of specialization, technology offerings (such as dense or dilute phase systems), and project experience in industries like food, pharmaceutical, chemical, and plastics.

Ready to request a quote or gather more information? Use the contact forms provided on each profile page to communicate directly with the company, or submit a request for quotation (RFQ) using our simple form to reach multiple suppliers at once. Our patented website previewer lets you quickly explore each company's core competencies, certifications, and completed projects—helping you make an informed purchasing decision.

Before selecting a supplier, consider asking the following questions:

- Does the company have experience designing systems for your specific material and application?

- Can they provide references or case studies from similar industries?

- What level of technical support, installation, and after-sales service do they offer?

- Are systems engineered to meet relevant industry regulations and safety standards?

- Do they offer on-site testing, pilot plant trials, or material analysis services?

- What is the expected lead time and project delivery schedule?

- How do their costs and warranty terms compare to other suppliers?

Choosing the right partner ensures a smooth project from design and installation to commissioning and long-term operation.

Frequently Asked Questions About Pneumatic Conveying

Looking for more information about pneumatic conveying solutions? Explore answers to common buyer questions:

- What materials can be conveyed pneumatically? Most dry powders, granules, pellets, and small particles—including food ingredients, chemicals, plastics, minerals, and pharmaceuticals—are suitable for pneumatic conveying.

- How do I choose between dense phase and dilute phase? Consider your product's fragility, density, and required conveyance speed. Dense phase is best for delicate or abrasive materials, while dilute phase is ideal for lightweight, free-flowing products.

- What are the main maintenance requirements? Pneumatic conveyors require periodic inspection of pipelines, blowers, filters, and valves. Regular cleaning and monitoring prevent blockages and ensure optimal performance.

- How can I reduce energy consumption in my system? Work with your supplier to optimize pipe routing, minimize unnecessary bends, select efficient blowers, and automate controls for energy savings.

- Can pneumatic conveying handle explosive or hazardous materials? Yes, with the correct system design (including explosion venting, ATEX-rated components, and dust control), pneumatic conveyors safely handle hazardous products.

- What is the typical payback period for a pneumatic conveying system? Payback depends on system complexity, energy savings, reduced labor, and maintenance costs, but most systems deliver ROI within 1–3 years.

Get Started: Request a Custom Pneumatic Conveying Solution

Ready to improve your material handling process with a modern pneumatic conveying system? Our directory connects you with leading manufacturers and integrators who can design, build, and install a system tailored to your specific needs. Whether you require a turnkey solution, retrofit, or system upgrade, our network ensures you find the best partner for your project.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services