Conveyor systems are common in various industries because they offer a cheap and efficient way to handle bulk materials while minimizing material loss. There are numerous types of conveying systems that can be utilized depending on the requirements of the specific business. Particles ranging in size from tiny granules to pellets can be handled pneumatically, making them useful for use in the construction and technology industries. Read More…

Volkmann designs and manufactures hygienic, explosion-proof pneumatic vacuum conveying systems to safely transfer powders, pellets, granules, tablets, and other bulk materials from one point in a process to another while safeguarding particle integrity. Proven worldwide in transferring foods, chemicals, pharmaceuticals, and more, the patented, automated conveyors eliminate the potential for...

Dynamic Air custom designs and manufactures a complete line of pneumatic conveying systems for dry bulk granular materials. Dynamic Air offers 16 different pneumatic conveying concepts, utilizing both pressure and vacuum, for handling a wide variety of dry bulk solids to provide a conveying solution that fits the process perfectly. Each system has its own unique set of operating characteristics...

Since 1946, Whirl-Air-Flow has been a leader in design, fabrication and service. Our pneumatic conveyors transport powders and dry granulars to one or more destination points. Our products serve a range of industries and are able to move flowable material. We have our own testing facility and also we provide customers with field support and services. If you would like more information please give ...

Founded in 1995, IEDCO specializes in custom-engineered powder handling solutions for the Pharmaceutical, Food, and Fine Chemical industries. From pneumatic conveying systems to comprehensive process designs, we deliver reliable, ergonomic, and innovative technologies. With decades of expertise and a client-focused approach, IEDCO is your single-source solution for tailored systems to enhance...

At Akona Process Solutions, we take pride in designing and delivering pneumatic conveying systems that keep bulk material handling safe, efficient, and reliable. We have built our expertise around developing equipment that moves powders, granules, and other bulk solids with precision, minimizing downtime and maximizing productivity for our customers.

When it comes to pneumatic conveying, Air Systems Design has been in business since 1984, a family owned business. Is dedicated to providing only the highest quality dust and baling systems available. Our team works together to ensure that we bring you the most technologically advanced products on the market, as well as that our company stays on the forefront of innovation at all times. To learn...

More Pneumatic Conveying System Manufacturers

Design of Pneumatic Conveying Systems

Pneumatic conveying systems are engineered solutions designed to efficiently transport bulk solids, powders, and granular materials through enclosed pipelines using airflow. The design phase is crucial and relies on a blend of scientific principles, real-world test data, and industry expertise. Mathematical models, test data, or a combination of both may be used to design a pneumatic conveying system. If mathematical models are to be used, some level of assurance regarding their fitness for a certain purpose, such as transmitting a specific material under precisely defined conditions, must be established before they are used. System design makes heavy use of test results. This information may have come from a testing facility or from sharing experience from a real plant.

It is crucial that the data pertain to the same grade of material that the new plant design is needed for. The data must also be supplied for a conveying line’s marginally lower level of intake air velocity and a marginally higher level of solids loading ratio than those considered for the new design. Existing data should never be scaled beyond limitations of known transmitting. As you evaluate pneumatic conveying system design for your facility, consider whether the design approach aligns with the specific properties of your material and the performance targets of your process.

Key Elements in Pneumatic Conveying System Design

Effective pneumatic conveying system design involves careful attention to multiple factors, including:

- Material characteristics: Flowability, particle size, bulk density, and abrasiveness.

- System capacity: Required material transfer rates and throughput.

- Pipeline layout: Distance, bend radii, and changes in direction.

- Airflow requirements: Pressure, velocity, and air-to-material ratio.

- Energy consumption: Optimizing blower or compressor sizing.

- Safety and compliance: Dust control, ATEX compliance, and food-grade standards.

Pneumatic Conveying System Design FAQs

How do I select the right pneumatic conveying system for my bulk material?

Begin by analyzing your material’s properties, required transfer rates, destination points, and environmental requirements. Consult with experienced pneumatic conveying system manufacturers to perform test trials and system modeling.

What is the role of test data in pneumatic conveying system design?

Test data validates design models and ensures reliable operation under real-world conditions, minimizing the risk of blockages, wear, or material degradation.

Structure and Functionality of Pneumatic Conveying Systems

At their core, pneumatic conveying systems are composed of several integrated components that work together to move bulk materials efficiently and safely. The primary elements include a material insertion point (feed hopper or inlet), conveying pipelines, a receiving point (discharge hopper or silo), and an air movement device such as a blower or vacuum pump. These systems are highly adaptable, with configurations tailored for specific industries and applications—from food processing to chemical manufacturing and plastics handling.

Pneumatic conveying system pipes are adaptable and may be routed around machinery, allowing them to be installed in existing locations. A practical, affordable method of moving products from point A to point B, well-designed pneumatic conveying systems are more efficient than competing mechanical systems. These systems offer a complete enclosure that minimizes dust emissions and contamination, supporting both industrial hygiene and regulatory compliance.

A pneumatic system is an industrial conveyor system that can travel large distances vertically or horizontally and provides protection from dust emissions into the air. Comparatively speaking, mechanical conveying systems, maintenance, equipment, and operating costs are decreased. Pneumatic conveyors also allow for multi-point loading and discharge, making them ideal for process plants with complex material flow requirements.

Pneumatic Conveyor Applications

- Transport of powders, granules, pellets, and flakes in food, chemical, pharmaceutical, and plastic industries

- Transfer of bulk materials in cement, mining, and mineral processing plants

- Dust collection and recycling in manufacturing environments

- Ingredient handling in bakery, beverage, and dairy plants

- Closed-loop conveying for inert material transfer in hazardous environments

Pneumatic Conveying Methods

The materials are moved using air streams, either vacuum or pressure, and there are three main types of pneumatic conveyor methods: dense phase conveying, dilute phase conveying, and air conveying. These methods operate in relation to, and in accordance with, the specific velocities, pressures, and air to commodity ratios within the system. Each method is suitable for different types of bulk materials and transfer requirements.

Dilute Phase Conveying

Continuous, high velocity, low pressure, and high air-to-commodity-loading ratio processes are used in dilute phase conveying. Pulling or pushing material through an airstream at a certain speed helps the process. Positive pressure, vacuum (negative pressure), or a combination of the two can be used to build the system. Dilute phase pneumatic conveying is ideal for lightweight, non-abrasive materials such as flour, sugar, and plastic pellets, and can efficiently handle long conveying distances.

Dense Phase Conveying

Dense phase conveying operates at lower velocities and higher pressures, making it suitable for fragile, abrasive, or heavy bulk materials—such as minerals, cement, or specialty chemicals. This method reduces material degradation and minimizes pipe wear, making it a preferred choice for applications requiring gentle handling or high throughput. Dense phase systems often utilize plug flow or pulse flow to move materials in a controlled manner.

Vacuum vs. Pressure Systems

Pneumatic conveying systems operate without exposing the materials being moved to moving parts because they are enclosed. Pressure systems input compressed air at the insertion or system inlet to force materials through, while pneumatic vacuum systems administer a vacuum at the receiving end to pull the material through the enclosed pipes. The selection between pressure and vacuum conveying depends on plant layout, material characteristics, and hygiene requirements.

- Vacuum systems: Ideal for multiple pickup points and short distances, especially where dust control is critical.

- Pressure systems: Better suited for long distances and multiple discharge points. Suitable for dense phase conveying.

Which Pneumatic Conveying Method Is Right for You?

Are you unsure which conveying technology best fits your process needs? Consider your material’s abrasiveness, required throughput, system distance, and sensitivity to degradation. Reach out to a pneumatic conveying system specialist for a comparative analysis of dilute phase vs. dense phase solutions.

Considerations When Choosing Pneumatic Conveying Systems

Selecting the right pneumatic conveying system involves a detailed evaluation of both process requirements and material properties. The following factors should be carefully reviewed during system specification and design:

- Particle size, shape, and distribution

- Air humidity and moisture content

- Material concentration and bulk density

- System throughput requirements and operational capacity

- Conveying distance, pipeline routing, and elevation changes

- Angles of flow, repose, and slip

- Material fluidization and flowability

- Hardness, friability, and potential for attrition

- Temperature stability and thermal sensitivity

- Compatibility with existing process equipment

- Maintenance requirements and lifecycle costs

- Compliance with food, pharmaceutical, or ATEX regulations

How to Evaluate Pneumatic Conveying System Options

Looking to compare the best pneumatic conveyor solutions for your facility? Start by consulting with multiple reputable pneumatic conveying equipment manufacturers and request detailed proposals. Ask about system modeling, on-site testing, installation support, and ongoing maintenance. Use our RFQ tools to easily compare price, lead times, and service offerings.

Areas of Application of Pneumatic Conveying Systems

Pneumatic conveying systems offer a versatile and cost-effective means of transporting a wide variety of bulk materials in numerous industries. Services provided by pneumatic conveying systems involve complete system engineering for systems applications like start-up service, full-scale material testing, spare parts and field service. They also convey difficult-to-handle material such as abrasive, attrition-sensitive or fragile products. Innovative feeder-control algorithms featuring second-to-second accurate performance can be applied even in aggressive plant environments.

These systems provide an extensive line of mechanisms for applications in the chemical, plastics, mineral, pet food, food, and pharmaceutical process industries while offering solutions for applications in very high sanitary demands and according to government specifications and customers. Leading industries leveraging pneumatic conveying technology include:

- Food and beverage: Flour, sugar, spices, grains, and coffee bean transfer

- Pharmaceuticals: Tablet ingredients, active compounds, excipients

- Plastics: Polymer pellets, resin transfer, colorants, and additives

- Chemicals: Reactive powders, catalysts, hazardous or toxic substances

- Minerals and mining: Cement, lime, fly ash, sand, and mineral ores

- Pet food and animal feed: Ingredients blending, mixing, and transfer

- Energy and power: Fly ash handling, biomass, and fuel injection systems

Typical Use Cases for Pneumatic Conveying Systems

- Automated ingredient delivery in food and beverage processing plants

- Centralized vacuum cleaning systems in manufacturing facilities

- Closed-system transfer of toxic or sensitive chemical compounds

- Batch and continuous transfer in pharmaceutical manufacturing

- Bulk resin feeding and blending in plastics compounding lines

- High-purity transfer in electronics and specialty chemical production

Advantages of Pneumatic Conveying Systems

Pneumatic conveying systems offer a range of compelling benefits over traditional mechanical conveyors, making them the preferred choice for a variety of bulk material handling applications. The advantages are as follows:

- A pneumatic conveying system allows greater versatility than a mechanical conveying system because it may be compatible with existing equipment due to the small nature of the conveying pipe’s transfer line.

- These systems can cover a large distance running either horizontally or vertically, making them ideal for multi-level and spread-out plants.

- Due to the enclosure of the system, both the delivered material and dust emission to the atmosphere are protected from outside contaminants. This ensures compliance with occupational safety, hygiene, and environmental standards.

- Because they have fewer moving components than mechanical conveying systems, pneumatic conveying systems can be simpler and more cost-effective to maintain. Lower maintenance needs translate to reduced downtime and operational costs.

- They maintain a capacity to keep the environment around the substance under control, which is critical for hazardous, toxic, or sensitive materials.

- They reduce abrasive material wearing on the system and fragile materials damage, supporting longevity and gentle handling.

- These systems are easier to find because they occupy less floor space, maximizing usable plant area and enabling installation in tight locations.

- Various pick-up and discharge points are possible, providing flexible integration with process equipment and enabling automated, multi-point distribution.

- Pneumatic conveyors support fast changeovers and cleaning for sanitary or multi-product operations.

- Closed pipeline systems minimize operator exposure, supporting worker health and safety.

- Energy-efficient designs are possible, particularly in well-optimized dense phase systems.

Why Invest in Pneumatic Conveying Technology?

Are you considering an upgrade from mechanical to pneumatic conveying? Evaluate how pneumatic systems can help reduce maintenance, increase process flexibility, and support regulatory compliance—especially in industries with strict hygiene, dust control, or contamination prevention requirements.

Choosing the Proper Pneumatic Conveying System Manufacturer

To make sure you have the most beneficial outcome when purchasing a pneumatic conveying system from a pneumatic conveying system manufacturer, it is important to compare at least 4 companies using our list of pneumatic conveying system manufacturers. Each pneumatic conveying system manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each pneumatic conveying system business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple pneumatic conveying system businesses with the same message.

How to Choose the Best Pneumatic Conveying Supplier for Your Needs

- Look for manufacturers with proven expertise in your industry and material type.

- Ask for references, case studies, and system performance guarantees.

- Evaluate after-sales support, spare parts availability, and maintenance services.

- Request pilot testing or system simulation to confirm suitability for your application.

- Compare warranty terms, lead times, and compliance with relevant standards (e.g., FDA, USDA, ATEX).

Frequently Asked Questions About Pneumatic Conveying Procurement

What questions should I ask a pneumatic conveying manufacturer before purchasing?

- What experience do you have with my specific material?

- Do you offer on-site testing or system modeling?

- How do you handle installation, commissioning, and training?

- What is the expected maintenance interval and spare parts availability?

Can I retrofit a pneumatic conveying system into my existing facility?

Yes, most systems can be engineered for integration with existing process equipment. Discuss your plant layout and constraints with the manufacturer for a tailored solution.

How do I request a quote for a pneumatic conveyor system?

Use our online RFQ tool to submit your requirements to multiple manufacturers and compare responses with ease.

Get Started With Pneumatic Conveying Solutions

Are you ready to optimize your material handling with a modern pneumatic conveying system? Explore our comprehensive resources on pneumatic conveying technology, compare leading manufacturers, and request a custom proposal tailored to your process needs. For more in-depth information, explore these related topics:

- Dense Phase Conveying Benefits

- Dilute Phase Conveying Explained

- Find Pneumatic Conveying System Manufacturers

For personalized support, contact our experts or schedule an on-site consultation today. Improve your plant’s efficiency, cleanliness, and safety with the latest in pneumatic conveying innovation.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

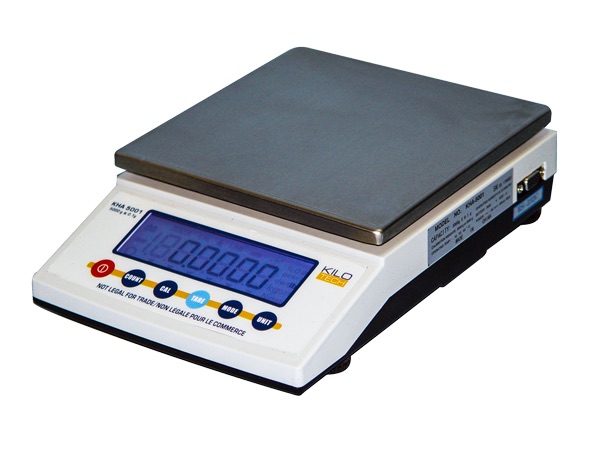

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services