There are many excellent benefits to pneumatic conveyors that make them an excellent choice for transporting materials quickly from one place to another. Before writing off a pneumatic conveyor immediately, consider the following benefits of this effective conveyance system:

Controlled dust: All dust associated with moving a loose material from one place to another is contained inside the conveyor tubes. This prevents the need for employees to wear masks, and it also prevents waste through the loss of material in a dust cloud.

Location flexibility: Pneumatic systems are flexible and can use a variety of shapes to fit into any existing factory room or warehouse. The tubes can travel around other machines, or over them, for the ultimate flexibility and space maximization.

Multiple pick-up points: Pneumatic conveyors can transfer materials from one source point to multiple output points. This makes it ideal for use in packaging and helps increase the overall transfer speed of the material.

Inexpensive maintenance: Although it costs more to install a pneumatic system to begin with, the maintenance on the unit is inexpensive. This is due to the lack of components in the system. The simple air blowing systems keep the material moving quickly, and make it easy to address problems when they arise.

Low contamination: Open transfer of materials can often become contaminated with dust, dirt, grease, insects, and even animal waste. Enclosed tubes, like the pneumatic system prevents the contamination of the material because it is never exposed to the outside air. The material moves from the original container to the package in a clean, sanitary way.

Bulk Bag Handling

Bulk Bag Handling Industrial Dryers

Industrial Dryers Mixers & Blenders

Mixers & Blenders Palletizers

Palletizers Pneumatic Conveyors

Pneumatic Conveyors Screw Conveyors

Screw Conveyors Vibratory Feeders

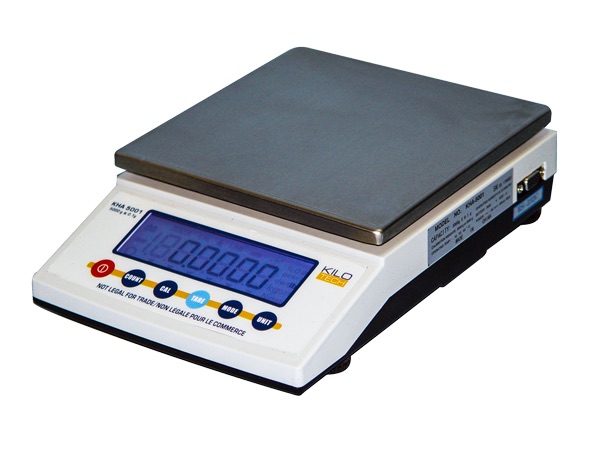

Vibratory Feeders Weighing Systems & Scales

Weighing Systems & Scales Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services